Photo Credits: by Christopher Burns

In the manufacturing industry, optimization is the key to survival and success. To keep up with today's demands for quick delivery and excellent quality, many companies have turned to connected technology to make their warehouses more innovative, efficient, and competitive. With new technological advances, many companies are assessing how to take advantage of the Internet of Things (IoT) to build more intelligent operations that allow for higher productivity and output. After all, IoT helps manufacturers to change to a more responsive, connected, and more innovative manufacturing industry.

This brings to some questions: what is smart manufacturing? Or a smart factory? And how can IoT add benefits to this industry? Let's find out the answers to all of these questions!

What is Smart Manufacturing?

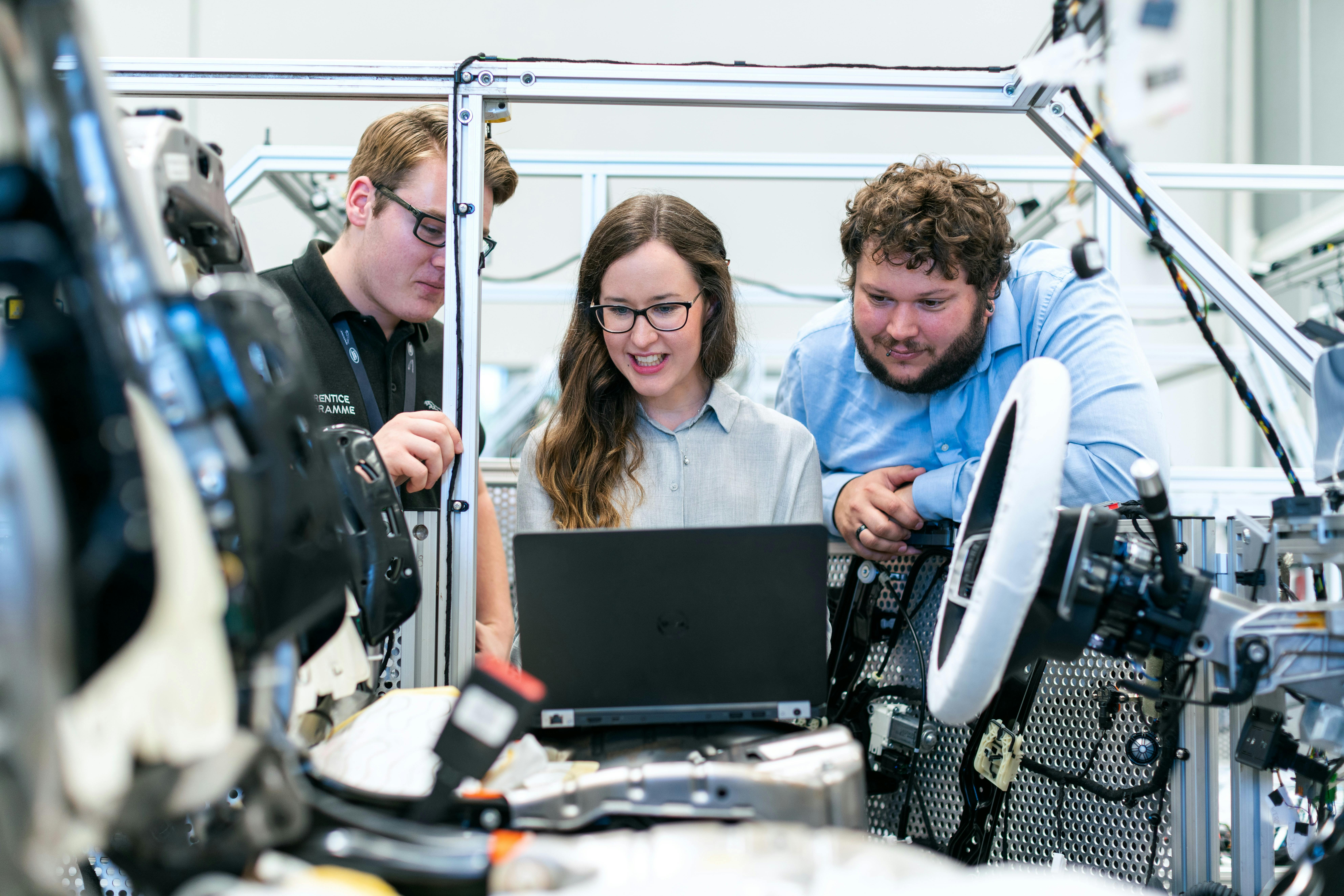

Photo Credits: by ThisisEngineering RAEng

Smart manufacturing uses Internet of Things technology and automation in manufacturing processes to ensure that productivity is continually optimized. Using Indoor Intelligence to precisely track assets and help provide worker safety while increasing productivity and improving security on the production floor is key to activating all the benefits of transforming your manufacturing and warehousing facilities into intelligent spaces. In the last year, the manufacturing industry has been embracing digital transformation in a big way. This translates into emerging industrial applications, including AI, cloud computing, IoT connectivity, predictive analytics, quantum computing, innovative additive fabrication technologies, and a host of other technologies. Together, these technologies marked the begging of the fourth industrial revolution and helped this industry to become more innovative.

What is a Smart Factory?

Photo Credits: by Lenny Kuhne

A smart factory is considered a highly digitized shop floor that regularly collects and shares data through all the factory's connected machines, devices, and production systems. It consists of a factory where physical production processes and operations are combined with digital technology to create a more opportunistic system for businesses that focus on manufacturing and supply chain management. The smart factory is integrated into Industry 4.0, a new phase in the process of the Industrial Revolution that concentrates massively on real-time manufacturing and logistics data, embedded sensors, connectivity, automation, and also machine learning.

As factories continue to evolve in light of the data revolution, businesses need to rethink how they handle everything from automation to workforce development tactics. Moreover, manufacturers will need to modernize their equipment, as well as the company resource planning systems as a data and transactional determination that will help them adapt quickly as they build toward a future factory.

By connecting both digital and physical worlds, smart factories can monitor the entire production process, from manufacturing equipment and the supply chain to individual workers on the shop floor, and make impactful incremental improvements.

The advantages of intelligent factories and warehouses

They include:

- Removal of digital distraction

- Employee safety

- Asset tracking

- Emergency preparedness

- Automation and operational efficiencies

- Environmental monitoring (temperature, humidity, Etc.)

- Access to predictive analytics

With all these advantages in place, companies would be wise to use innovative technology to improve their manufacturing procedures. As internet-enabled objects become more common and integrated with location-based services, businesses can provide employees with location-aware solutions that elevate operational efficiency and productivity. The abundance of opportunities for applications that incorporate machine learning with indoor maps is endless in the manufacturing and warehousing sector. With the correct base elements, new possibilities are uncovered when organizations embrace the potential of industrial IoT technologies.

Photo Credits: by ThisisEngineering RAEng

In conclusion, Industry 4.0 technologies can enhance, enable, and augment each other as systems clearly define that it is a crucial change in the industry.

Using indoor positioning with the help of sensor technology or by leveraging the existing technology ecosystem of the company allows users to precisely pinpoint the location of teams or equipment inside a building using any mobile devices, tracking beacons, or other types of devices. By using a variety of sensors, the IPS technology will detect and track data about any device's location. Using the location data will give more accurate coordinates displayed on an indoor map, leading to unparalleled visibility of complex factory facilities and transmitting the environment inside them.

Location awareness is without a doubt one of the essential benefits of this industry. After all, by receiving this multidisciplinary depiction of indoor data, users will see an increase in revenue, the reduction of costs, and most importantly, the improvement of safety.